Our services

Comprehensive Services for Every Challenge

Explore our range of expert solutions designed to help you succeed.

System Integration & Support

![]()

- End-to-End System Integration: Seamless integration of automation systems with existing infrastructure and business processes.

- Legacy System Upgrades: Upgrading and modernizing outdated automation systems to improve performance and compatibility.

- 24/7 Technical Support: Offering round-the-clock troubleshooting, support, and remote assistance.

- On-Site Commissioning: Full system deployment and testing at the client’s facility, ensuring smooth operation of the system.

- Training and Documentation: Providing training for staff and creating detailed documentation for easy system management and future troubleshooting.

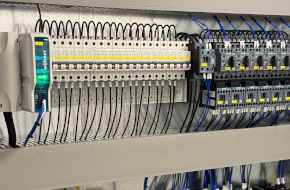

Control Systems Design & Engineering

![]()

- Custom Control System Design: Tailored automation solutions based on industry-specific needs and applications.

- PLC Programming: Development and programming of PLCs (Programmable Logic Controllers) for process automation on all major platforms.

- HMI Development: Human-Machine Interface design for intuitive operator control and data visualization.

- System Optimization & Testing: Ensuring the reliability and efficiency of control systems with comprehensive testing and optimization, with as much, or as little involvement with the end user as required

Safety Standards & Compliance

![]()

- Compliance with Industry Standards: Ensuring automation systems meet global safety regulations such as BS EN 13849 and BS EN 60204

- UKCA Marking & Certification: Assistance with obtaining UKCA (previously CE) certification for machinery and systems in compliance with European safety laws.

- Functional Safety Engineering: Designing systems with functional safety in mind, ensuring protection from hazardous machine failures.

- Safety Audits & Reports: Conducting audits to ensure systems comply with safety regulations and industry best practices.

- Training on Safety Practices: Providing training for operators and engineers to ensure safe machine operation and awareness of hazards.

Machinery Safety

![]()

- Safety Risk Assessments: Comprehensive evaluations to identify potential hazards and improve overall machine safety in accordance with BS EN 12100

- Safety PLC & Controls: Design and implementation of safety PLCs for ensuring compliance with safety standards and regulations.

- Machine Safety Integration: Integration of safety features into existing automation systems to enhance operator protection.

- Emergency Stop Systems: Implementation of emergency stop buttons and other quick-response systems to minimize risk in critical situations.

Is your engineering department struggling?

- Lacking engineering skillsets?

- Is your plant seeing an increasing amount of downtime?

- No source for reliable spare parts?

- Just can't find the root cause of an ongoing breakdown?

- Are you aware of all your obsolete hardware? What are you doing about it?

We have got the answers...

- Our Technical Support Team offer 24/7 breakdown cover!

- We offer continuous improvement works to help reduce your downtime and keep your plant running efficiently!

- We can quickly source both current and obsolete parts for you, no hassle!

- We'll support your team to diagnose you with a permanent solution to prevent further downtime!

- Let us do the leg work, we can undertake an obsolescence survey for you and provide a full report of where your vulnerable kit is. We'll even support you with upgrading parts to get your plant back up to date!